MOLD DESIGN & MANUFACTURING

Through discussions with our clients, we are able to satisfy their conditions by provding a one-stop service, from design, manufacturing, to assembly and product testing.

Through discussions with our clients, we are able to satisfy their conditions by provding a one-stop service, from design, manufacturing, to assembly and product testing.

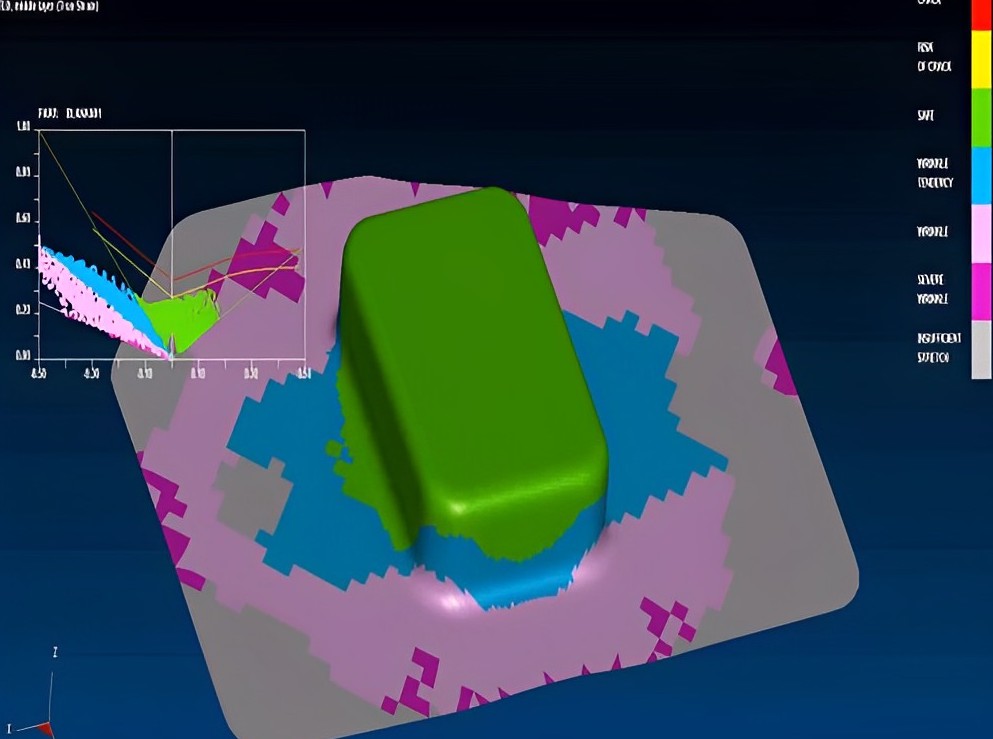

We undertake feasibility evaluation according to our APQP process. Our design team includes sales, design engineering, QC and on-site personnel, in order to ensure the realization of the customer's needs.

JUMPWAY currently has a robust list of precision machinery equipment: Wire and Laser Cutting, Surface Grinding, Miling, Drilling, Lathe, Bending, NCT Machines, as well as CNC Machining Centers.

We have an abundance of experience in fabrication and inspection according to customer drawings, in-house design, drafting material preparation and processing, heat treatment, wire cutting, and assembly, allowing us to make timely discovery and correction of any problems.

We then determine whether the Quality Control plan is feasible, and verifies that the mold efficiency and the overall quality of parts produced comply with our customers needs for mass production.